Tile Effect Metal Roofing Sheet Roll Forming Line

This cold roll forming machine is designed for producing metal roof tiles which becomes more and more popular using as roofing cladding. Main material can be roll formed are PPGI coils, GI coils, PPGL coils and GL coils with 0.5mm to 0.8mm thickness.

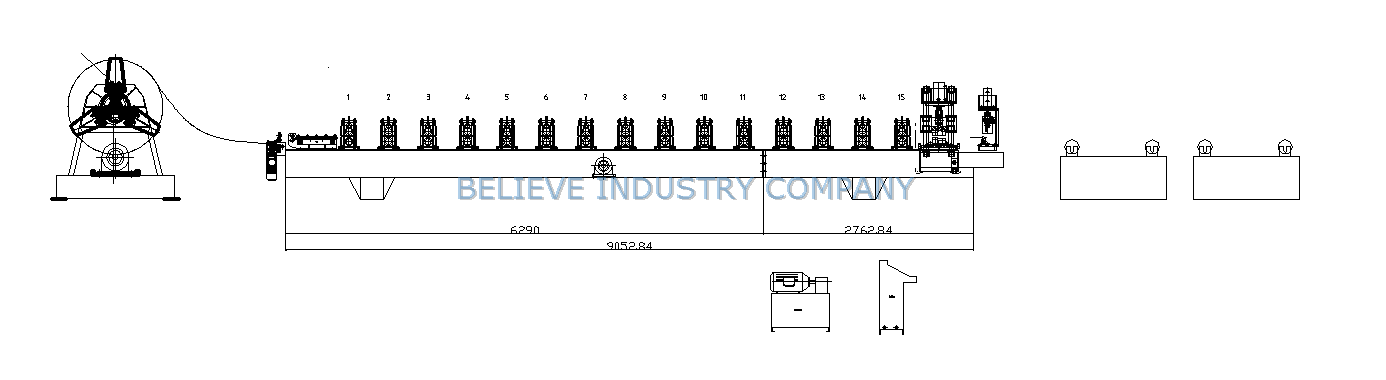

Whole line is highly automatic combining cold roll forming technology, punching pressing technology and electric control system. Main components are decoiler, metal tile rollformer, tiles pressing unit, cutting unit, hydraulic station and PLC control system.

| No. | Model: YX25-200-1000 Metal Tile Roof Panel | |

| 1. | Effective Width | 1000mm |

| 2. | Feeding Width | 1220mm (depend on specific profiles of the roofing sheet) |

| 3. | Material Thickness | 0.5-0.8mm |

| 4. | Application | Roof Cladding |

| 5. | Material Type | PPGI, GI coils, Color Steel Coils |

Advantages of This Machine

1. Guide pole side structure for easily adjust rollers

2. Material of rollers is GCr15, stronger and more wearable

3. Hydraulic station is equipped with air cooling

4. Equipped with protective cover, ensure the safty of people and machine

5. All eclectric parts and hydraulic elements are selected from famous brand

6. Easy operation and maintenance.

| No. | Item and Technical Parameters | |

| 1. | Uncoiler / Decoiler | 5Ton single mandrel type hydraulic decoiler |

| 2. | Machine Base | H beam steel welded structure |

| 3. | Roller Stands | Guide-pillar type roller stands, all with heat treatment |

| 4. | Diameter of Shaft | 75mm / 76mm |

| 5. | Material of Shaft | 40Cr, surface with 0.05mm Chrome plated |

| 6. | Material of Rollers | GCr15, surface with 0.05mm Chrome plated |

| 7. | Main Power | 11KW |

| 8. | Forming Speed | 10-15m/min; whole line speed: 3-4m/min |

| 9. | Roller Stations | 18-24 stations |

| 10. | Cutting Type | Hydraulic cutting, stop to cut |

| 11. | Material of Cutting Blade | Cr12 Mov, HRC58-62° |

More Pictures of Metal Tile Roofing Machine

Competitive Advantages Of Believe Industry Company

- Annual export of roll forming equipment is more than 180 sets to over 80 countries and regions of the world.

- We have our own team for reseaching and developing, we keep improving our technology in machine design and manufacturing.

- All material are select from famous brands, and we have strict quality control on material processing.

- Professional after-sale service relieve clients from all kinds of worries.

If you need more machine details, please contact us directly.