Automatic Adjustment C Z Purlin Roll Forming Machine

Believe Industry Company designs and makes roll forming machine for producing C purlins, Z purlins, U purlins and M purlins, etc. Based on customers' requirement, we have different machine designs, economical machine design(manual adjustment), high speed machine design(automatic adjustment), etc.

This CZ purlin changeover roll forming machine can produce both C purlins and Z purlins by automatic adjustment. With the independent punching system, gear box transmission system and servo-motor-tracking cutting device, whole line speed can reach up to 12-15m/min.

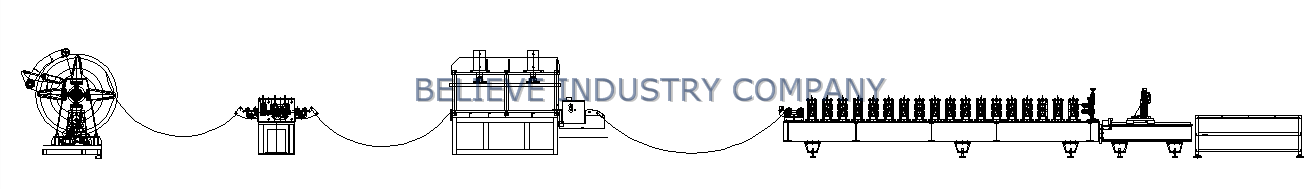

Main Componants of The CZ Changeover Purlin Production Line

1. Machine workflow: uncoiling - levelling - punching - roll forming(gear box transmission) - nonstop cutting - stacking

2. Final machine design and layout will be according to customers' requirement.

Main Technical Parameters

Decoiling Unit

1. Decoiler Type: hydraulic decoiler (hydraulic coil expansion and tension, electric unwinding)

2. Loading Capacity: 6000kgs

3. Max Coil Width: 600mm

4. Coil Inner Diameter: 450-530mm

5. Coil Outer Diameter: Max 1350mm

Levelling and Punching Unit

1. Levelling rollers: 5 rollers for levelling, up 2 rollers and bottom 3 rollers

2. Levelling power: 1.5kw

3. Material of Levelling Roller: 40Cr, 110mm in diameter

4. Punching Type: hydraulic powered punching, punching before roll forming

5. Hydraulic Power: 7.5kw

6. Material of Punching Mold: CR12, HRC 58-62 degree

Main Roll Forming Unit

1. Rolling steps: 14 steps (14 roller stands)

2. Shaft: 75mm in diameter; 40Cr

3. Roller material: GCr15, HRC58-62

4. Power for roll forming: 18.5kw

5. CZ changeover: manually adjustment,

6. CZ purlin dimension adjustment: automatic adjustment, electric motor 1.5kw*2

7. Drive and transmission: electrically motor drive; driven by gear box and universal joint

8. Whole line speed: 12-15m/min (including punching and cutting)

9. Cutting Type: hydraulic cutting, servo-motor-tracking type non-stop cutting

10. Material of Cutting Blade: Cr12Mov, HRC58-62

11. Cutting Power: 7.5kw

12. Universal cutting blade: one set of cutting blade for cutting all the dimensions, easy manual adjustment

If you need more machine details, please contact us directly.