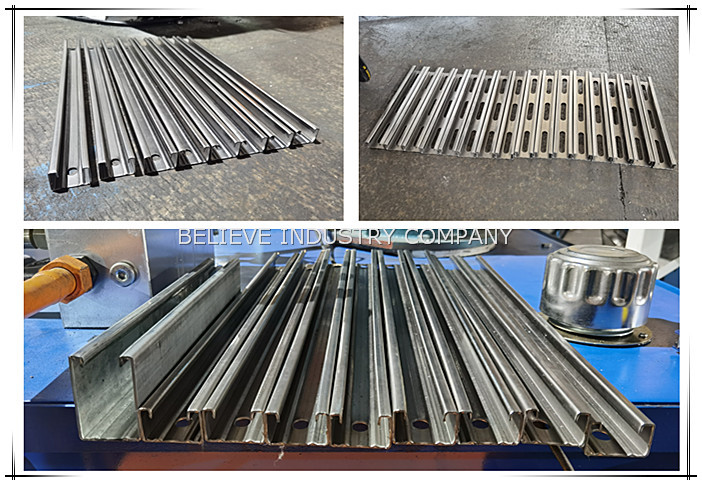

41 * 21 / 41 * 41 / 41 * 61 / 41 * 81 Peforated Solar Strut Channel Roll Forming Machine

The steel C-shape strut channels are cold roll formed sections working as the support frames for solar panels. Believe Industry Company designs and makes solar strut channel forming machine for producing various sizes (41 * 21 & 41 * 41 & 41 * 61 & 41 * 81 or as per customers' profile drawings).

We have economical machine designs and high productivity machine designs according to customers' requirement. The solar strut machine as the video shows is an ecomonical design. The whole line speed is approx. 3-5m/min including punching and cutting. Believe Industry Company also offers high speed machine with the whole line speed up to 30-40m/min.

Main Components of the Strut Channel Production Line

- Decoiler

- Levelling Unit: 7-roller levelling the sheet for good flatness before roll forming

- Roll Forming Unit: economical machine design with electrially motor drive via chain

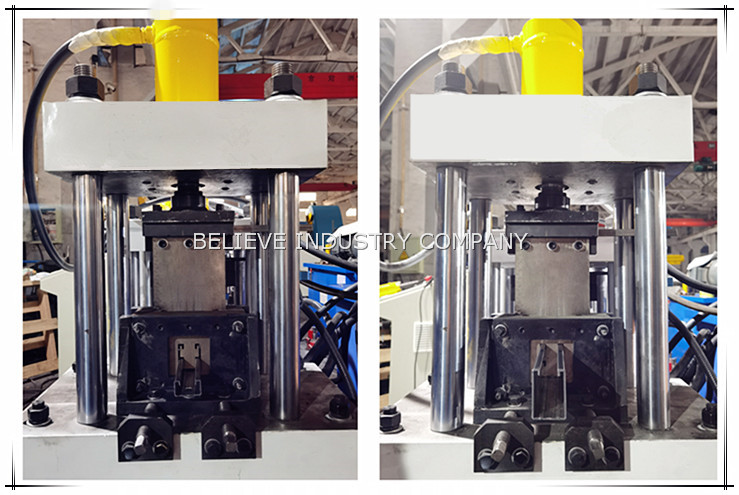

- Hydraulic Punching Device: post punching type

- Hydraulic Cutting Device: hydraulic cutting, stop cutting type

- Runout Tables: unpowered type supporting tables

- Electric Control System: automatic PLC control system, famous brand electric components

- Hydraulic station: offer power for punching and cutting

Main Technical Parameters

| No. | Item | Specifications |

| 1. | Dimensions of Strut Channels | 41 * 21, 41 * 41, 41 * 61, 41 * 81 or as required |

| 2. | Material Applicable | Hot rolled / cold rolled steel coils, galvanized steel coils, 1.5mm - 2.5mm thickness |

| 3. | Size Adjust | Manual adjust the rollers and spacers |

| 4. | Decoiler | manual type or electric type or hydraulic type depend on custmers' requirement |

| 5. | Machine Structure | high quality H beam steel welded machine base, steel plate welded support panels |

| 6. | Roller Stations | 22 roller stations / forming steps |

| 7. | Main Power | 11kw |

| 8. | Forming Speed | 12-15m/min |

| 9. | Hydraulic Power | 7.5kw |

| 10. | Material of Levelling Rollers | 40Cr, solid shafts, 90mm inner diameter |

| 11. | Material of Forming Rollers | High quality No.45 steel, with heat treatment and tempered, Chromed |

| 12. | Material of Punching Mold | Cr12Mov, HRC58-62 |

| 13. | Material of Cutting Blade | Cr12Mov, HRC58-62 |

| 14. | Cutting Length Tolerance | ±2mm |

| 15. | Electric Control Cabinet | Panasonic PLC, YASKAWA frequency converter, Omron encoder, or Siemens, etc |

More Pictures For Reference

Contact us for more machine details.